Descripción

Every line is custom made, design upon customer’s specification request.

MAIN STANDARD CHARACTERISTICS

- Automatic unwinder (different models for any need)

- Primer/Release coating and drying unit

- Rotogravure system with “closed chambre doctor blade” or Mayer bar

- Primer/release feeding and recycle systems with tanks and pumps

- Vertical or horizontal hot air drying ovens with thermal blower modules

- Adhesive coating unit

- Coating head: rotating knife type, with knife and applicator rolls, parallel or overlapped arranged, prearranged for automatic correction

- Vacuum driven pull in exit

- Adhesive drying tunnel

- High efficiency horizontal ovens, shall opening type, film conveyance by means of idle or driven rolls

- Thermal blower modules: integrated or separated

- Each module can be dedicated to 1 or 2 sections of ovens

- Air heating with thermal oil, steam or overheated water batteries, or gas burners

- Equipment and devices for solvent prevention

- Insulating cabinets

- LEL monitoring systems (I.R. or Flame Temp. Analyser type)

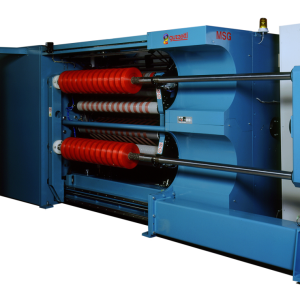

- Draw and cooling unit with water cooled cylinders

- Anti-surface treatment

- For coating units inside frames and after coating web contact rolls. Eventually for nozzles and rolls inside release/primer/adhesive drying ovens.

- Automatic winder (different models for any need)

- Equipment and devices for the good control of the web

- (Spreader rolls, antistatic devices, tension control devices…)

FITTING AND OPTIONS

- Rotogravure system with “closed chambre doctor blade” or Mayer bar

- Primer/release feeding and recycle systems with tanks and pumps

- Vertical or horizontal hot air drying ovens with thermal blower modules

- Coating head: rotating knife type, with knife and applicator rolls, parallel or overlapped arranged, prearranged for automatic correction

- Vacuum driven pull in exit

- High efficiency horizontal ovens, shall opening type, film conveyance by means of idle or driven rolls

- Thermal blower modules: integrated or separated

- Each module can be dedicated to 1 or 2 sections of ovens

- Air heating with thermal oil, steam or overheated water batteries, or gas burners

- Insulating cabinets

- LEL monitoring systems (I.R. or Flame Temp. Analyser type)

- For coating units inside frames and after coating web contact rolls. Eventually for nozzles and rolls inside release/primer/adhesive drying ovens.

- (Spreader rolls, antistatic devices, tension control devices…)

Coating line can be equipped with:

- Reels loading-unloading systems

- Film stretching calenders group

- Corona treatment stations

- Other type of applicable adhesive coating heads

- Mayer bar, reverse roll, “comma” roll system…

- Other types of drying ovens:

- Both sides vertical opening type, air flotation type, driven conveyor belts type…

- Heat exchangers for energy recovery

- High temperature curing ovens

- Humidification system

- Secondary unwinder with lamination group

- Delaminating group with liner rewinder

- Web pre-conditioning groups: heated calenders or I.R. plates

- Web cleaning treaters

- Web surface inspection and monitoring system

- Coat thickness/basis-weight measuring system:

- Total basis weight type or differential synchronized measuring type, with eventually automatic adjustment of the coating die

- Supervision system with industrial PC